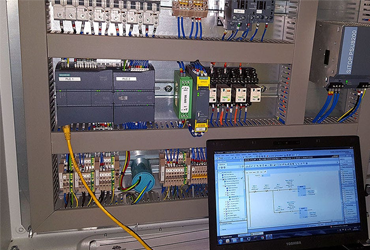

PLC Programming" involves the creation and implementation of logic used in Programmable Logic Controllers (PLCs) for automated control systems in industrial settings. Engineers and programmers write code that dictates how PLCs interact with machinery and processes, enabling precise automation of tasks such as manufacturing, packaging, and monitoring.

Key tasks include designing logic diagrams, writing code in programming languages like ladder logic or structured text, and testing to ensure functionality and safety. PLCs are essential in industries for their reliability, speed, and ability to operate in harsh environments. They facilitate real-time monitoring, data collection, and decision-making based on inputs from sensors and other devices.

Continuous optimization and troubleshooting are integral to PLC programming, ensuring efficiency and adherence to safety standards. Advancements in PLC technology, such as integration with Industrial Internet of Things (IIoT) platforms, further enhance their capabilities in data analytics and remote monitoring. Effective PLC programming enhances operational efficiency, reduces manual labor, and improves overall productivity in industrial processes.